| SwitchAir Metal Domes |

|

KEY DOME ARRAYS

Nicomatic is one of the world's fastest growing and

one of the largest manufactures of dome arrays. Our arrays are produced

in Class 10,000 clean room environments with ISO9002 certification. Our

factories are located in France, Korea, Hong Kong and North America ensuring

that we can meet your needs anywhere in the world.

The key dome array has become one of the most cost

effective solutions for providing a switching mechanism with a superior

tactile effect and feel between your equipment and the user. Pre-positioned

key dome arrays have been designed to be simple and quick to use in assembly,

just remove the liner from the array and it can be stuck straight down

to the pcb or flexible circuit.

Dome arrays offer a number of advantages and feature

|

|

|

Applications can be wide and varied covering any product that requires switching inputs from the user. Dome arrays have become very popular for use in mobile applications as they have can offer some very positive advantages over the use of a polydome layer as highlighted below

|

Dome array utilising N6.4 4leg 170

|

Ventilation

Ventilation is provided via the kiss cut or via chanels in the spacer

layer connecting the various dome chambers. The pcb ventilation holes

are therefor no longer required thus enabling more creativity with your

designs.

Array Components

A sampling of each component is controlled to Nicomatic's

requirements before being accepted for use in our dome array production.

Domes

Arrays of domes can be produced using our comprehensive

range of metal domes (select here for

link). Our established production process's ensures:-

- Stable forces of domes

- Excellent tactile feel even after rigorous overload teste

- Control of dimensional tolerance

- No burrs, thus reducing wear on the substrate

- Successful and reliable automatic placement with equipment which enables high production capacity

Polyester/adhesive carrier

The standard material used is a 0.05mm polyester plus

a 0.03mm sheet of acrylic adhesive

Control and qualification of components

To ensure a high quality product wide ranges of tests

are conducted: force, tactile feel, life expectancy,electrical contact

Mechanical

Metal domes are characterised by a Force/Travel curve.

A typical curve is depicted below. The two curves represent the make cycle

and the break cycle when a metal dome is actuated.

- The make cycle is the higher of the two curves and represents the force and travel of the metal dome as the dome is depressed.

- The lower curve (break cycle) represents the force

and travel of the dome as it is released

The curve shown here does not take into consideration effects of the keypad and the mounting

- The trip force Ft is the maximum force required to activate the dome

- The rebound force Fr is the amount of force applied by the metal dome during its release. If the overlay or keypad requires more force than this during the release in order to make the return, the metal dome will not be able to release.

- The contact force Fc shown on the curve represents the amount of force being applied when contact is made with the lower surface.

Qualification testing

Life expectancy

The dome is submitted to 3 million actuations. The

trip force and the rebound force are measured during the test and must

continuously meet mechanical and electrical requirements.

Overload test (static load)

These tests vary in the amount of force, the duration

of application of the force and the number of cycles required. The acceptance

criteria difer from the test strength. The dome must meet all mechanical

and electrical requirements during and after the test.

Overstroke

The rebound force of the dome is measured during an

over travel condition. Nicomatic's domes react very well.

Position of the actuator shifted from the dome

centre

The conditions of this test are similar to the life

expectancy test. The difference is that the actuator is not located in

the centre of the dome, but maximum 1mm of teh centre. The SwitchAir dome

demonstrates remarkable robustness to this test, indeed, the dome reacts

the same as is the actuator was in the centre.

Electrical measurement

Nicomatic measures the switching signal and the contact

resistance of the dome.

Assebly Height

As shown below, the height of the SwitchAir dome array

when assembled consists of the height of teh dome plus the thickness of

teh polyester/adhesive retainer.(N6.4 4leg 170 used in example)

| Characteristics | ||

|

Adhesive thickness | 0.08+/-0.01 |

| Dome height | 0.30 +/-0.08 | |

| Dome array height | 0.38+/-0.09 | |

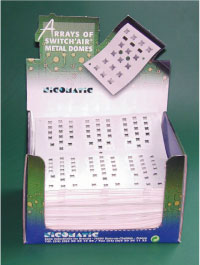

Packaging

|

Where standard sheets sizes are produced sheets of 4, 6 or 8 arrays are delivered in dispensing boxes individually sealed from the environment. |

Flexible tooling

Our tooling capabilities have been developed to offer

our customers a cost effective solution suitable for their project needs.

Prototyping samples can be supplied normally within 2-3 weeks from agreement

of specification. The option thereafter as to whether to move to a general

production tooling and produce the product on one of our specialist pick

and place machines or if the monthly requirement is substantial then tooling

can be produced for our fully automated MDA (mass dome applicator)

Application specialists